-

Strong built and reliable The baking units allow for automatic treatments like baking, roasting and cooking up to 200⁰C for meat, sausages and other products. The products can be hanged on trolleys or arranged on grates, thus increasing the loading capacity. For the best results during each process, we have developed our chamber using very strong materials and special upgraded insulation and reinforced panels with 100 mm thickness. In order to guarantee the uniformity of the products, our chambers use one fan for each trolley and one extra evacuation ventilator. The perfect coordination of the sizes and parameters results in shorter programs and improved yields thanks to the reduced loss. Additional features All Emerson Technik baking and roasting chambers are coming standard with an automatic cleaning system, cleaning agent dosing and also a water pressure pump (optional). The chambers are controlled either via the EasyTouch touch screen computer or with the ViSoft PC monitoring software (optional). Upon the customer’s demand, the baking chamber can be equipped with a glass door for better view and control of the baked products. Benefits:

Strong built and reliable The baking units allow for automatic treatments like baking, roasting and cooking up to 200⁰C for meat, sausages and other products. The products can be hanged on trolleys or arranged on grates, thus increasing the loading capacity. For the best results during each process, we have developed our chamber using very strong materials and special upgraded insulation and reinforced panels with 100 mm thickness. In order to guarantee the uniformity of the products, our chambers use one fan for each trolley and one extra evacuation ventilator. The perfect coordination of the sizes and parameters results in shorter programs and improved yields thanks to the reduced loss. Additional features All Emerson Technik baking and roasting chambers are coming standard with an automatic cleaning system, cleaning agent dosing and also a water pressure pump (optional). The chambers are controlled either via the EasyTouch touch screen computer or with the ViSoft PC monitoring software (optional). Upon the customer’s demand, the baking chamber can be equipped with a glass door for better view and control of the baked products. Benefits:- Reliability due to strong materials and processes

- Weight loss reduced to minimum

- Increased efficiency due to bigger loading capacity

- Complete control over the processes due to touch-screens and glass doors (optional)

-

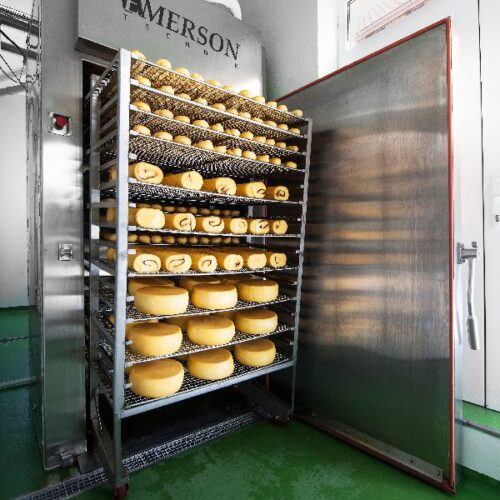

For smoked cheese application, Emerson Technik smoking chambers usually use the cold smoke system. The perfect air circulation, together with the low smoke temperature (controlled by the cooling register) ensure that the product will have less loss after the drying – smoking process and also a perfect maturation. The chamber is designed to have optional horizontal air circulation for laying products on the grates. Thanks to the horizontal air circulation, the trolleys can be constructed with many levels and the capacity will be increased. Also, the heating can be adjusted for maturation and humidity control. Our customers are welcome to choose from saw-dust, wood chips, friction or liquid smoke generators. Benefits:

For smoked cheese application, Emerson Technik smoking chambers usually use the cold smoke system. The perfect air circulation, together with the low smoke temperature (controlled by the cooling register) ensure that the product will have less loss after the drying – smoking process and also a perfect maturation. The chamber is designed to have optional horizontal air circulation for laying products on the grates. Thanks to the horizontal air circulation, the trolleys can be constructed with many levels and the capacity will be increased. Also, the heating can be adjusted for maturation and humidity control. Our customers are welcome to choose from saw-dust, wood chips, friction or liquid smoke generators. Benefits:- Reliability due to strong materials and processes

- Weight loss reduced to minimum

- Fast programs thanks to the design of the ventilating system

- Easy installation due to modular construction

- Complete control over the processes due to touch-screens

-

New technologies for better results The Emerson Technik smoking and cooking units are allowing automatic heat treatments for meat, fish or other food products. They benefit from very strong materials and from a special cooking system – QuickCook, which ensures reduced working time as well as overall better results. The weight loss is strongly improved leading to a better yield, but at the same time the product is uniformly cooked, as the chambers come with one fan for each trolley. Each cooking chamber is equipped with gas, LPG, diesel, oil or electric heating (besides the steam), thus ensuring the generous steam production inside the chamber. Also, chambers feature a modular construction from high quality stainless steel and mineral rock wool panels, which allow them to be installed in different locations, from small to mid-sized to high capacity factories. Features: Different cooking control options are also available, such as Delta T cooking, chamber temperature cooking or core temperature cooking. The chambers are controlled either via the EasyTouch touch screen computer or with the ViSoft PC monitoring software.

New technologies for better results The Emerson Technik smoking and cooking units are allowing automatic heat treatments for meat, fish or other food products. They benefit from very strong materials and from a special cooking system – QuickCook, which ensures reduced working time as well as overall better results. The weight loss is strongly improved leading to a better yield, but at the same time the product is uniformly cooked, as the chambers come with one fan for each trolley. Each cooking chamber is equipped with gas, LPG, diesel, oil or electric heating (besides the steam), thus ensuring the generous steam production inside the chamber. Also, chambers feature a modular construction from high quality stainless steel and mineral rock wool panels, which allow them to be installed in different locations, from small to mid-sized to high capacity factories. Features: Different cooking control options are also available, such as Delta T cooking, chamber temperature cooking or core temperature cooking. The chambers are controlled either via the EasyTouch touch screen computer or with the ViSoft PC monitoring software. -

Quicker, safer, better The defrosting technology is designed for fast, safe and controlled thawing of the frozen meat, fish or other products blocks. The process functions using gentle air circulation, humidity and temperature control, to give the customer the possibility to determine the time/loss balance. The difference between the core temperature and the surface temperature can be adjusted. The EasyTouch control system offers the possibility of automatic steps with interval waiting times. The system ensures low investment and flexible capacity comparing to traditional thawing systems. The chamber can be constructed welded, thus offering also mobility. The chambers are controlled via the EasyTouch touch screen computer or with the ViSoft PC monitoring software (optional).

Quicker, safer, better The defrosting technology is designed for fast, safe and controlled thawing of the frozen meat, fish or other products blocks. The process functions using gentle air circulation, humidity and temperature control, to give the customer the possibility to determine the time/loss balance. The difference between the core temperature and the surface temperature can be adjusted. The EasyTouch control system offers the possibility of automatic steps with interval waiting times. The system ensures low investment and flexible capacity comparing to traditional thawing systems. The chamber can be constructed welded, thus offering also mobility. The chambers are controlled via the EasyTouch touch screen computer or with the ViSoft PC monitoring software (optional). -

Our customers can choose from saw-dust, wood chips, friction or liquid smoke generators depending on their facilities and the desired products. The air flow can be vertical or horizontal for fish laying on nets. The heating can be either steam, gas, LPG, diesel, oil or electric, each system ensuring the reach of the desired parameters in optimal time. Benefits:

Our customers can choose from saw-dust, wood chips, friction or liquid smoke generators depending on their facilities and the desired products. The air flow can be vertical or horizontal for fish laying on nets. The heating can be either steam, gas, LPG, diesel, oil or electric, each system ensuring the reach of the desired parameters in optimal time. Benefits:- Reliability due to strong materials and processes

- Weight loss reduced to minimum

- Less energy consumption due to innovative airflow design

- Fast programs thanks to the design of the ventilating system

- Uniform products

- Complete control over the processes due to touch-screens

-

Complete process for chilling various products The cooling chambers are designed for fast chilling of various products. The cooling system functions within 2 stages, namely the pre-cooling water showering stage and the fast cooling with high humidity intensive fog stage. Thanks to the reduced cooling times in the temperature range (from 40⁰C to 15⁰C), the products’ shelf life is dramatically improved and the appearance is enhanced. The final core temperature of the product allows for immediate packing or slicing, therefore reducing the handling and storing costs. For increased flexibility, with optional extra heating, the chamber can also be used as a cooking chamber. Compared to conventional cooling, the weight loss is also improved. The chambers are controlled via the EasyTouch touch screen computer or with the ViSoft PC monitoring software (optional). Benefits:

Complete process for chilling various products The cooling chambers are designed for fast chilling of various products. The cooling system functions within 2 stages, namely the pre-cooling water showering stage and the fast cooling with high humidity intensive fog stage. Thanks to the reduced cooling times in the temperature range (from 40⁰C to 15⁰C), the products’ shelf life is dramatically improved and the appearance is enhanced. The final core temperature of the product allows for immediate packing or slicing, therefore reducing the handling and storing costs. For increased flexibility, with optional extra heating, the chamber can also be used as a cooking chamber. Compared to conventional cooling, the weight loss is also improved. The chambers are controlled via the EasyTouch touch screen computer or with the ViSoft PC monitoring software (optional). Benefits:- Improved shelf life for the product due to reduced cooling times

- Better appearance for the products due to the intensive process

- Reduced handling and storing costs due to the ability to immediately pack the products

- Flexibility (tthe chambers can also be used as a cooking chamber)

- Perfect control with EasyTouch and ViSoft PC monitor

-

Perfect for industrial production The mixing room chambers are designed for the industrial production and can have a capacity of two/four up to twelve trolleys. Our customers can choose from saw-dust, wood chips or liquid smoke generators, depending on their facilities and the desired products. All the EMERSON TECHNIK smoking and cooking mixing room chambers are coming standard with an automatic cleaning system, cleaning agent dosing and also an optional water pressure pump. Also optional are the chambers’ showering, cold smoke, horizontal air flow, automatic door opening, extra rear door/s or the catalytic afterburner.

Perfect for industrial production The mixing room chambers are designed for the industrial production and can have a capacity of two/four up to twelve trolleys. Our customers can choose from saw-dust, wood chips or liquid smoke generators, depending on their facilities and the desired products. All the EMERSON TECHNIK smoking and cooking mixing room chambers are coming standard with an automatic cleaning system, cleaning agent dosing and also an optional water pressure pump. Also optional are the chambers’ showering, cold smoke, horizontal air flow, automatic door opening, extra rear door/s or the catalytic afterburner. -

The Emerson Technik smoking chambers can be equipped with various OptiSmoke smoking generators, depending on the customer’s request or specific local regulations all over the word. Made from solid stainless steel material and resistant at high temperature, OptiSmoke can be used both for hot smoke as well as for cold smoke, given the different type of products. Depending on the application and the capacity of the chamber, we provide the right OptiSmoke smoke generator. It can be ordered for sawdust, wood-chips, friction or liquid smoke. All types of smoke generators are automatic controlled by the main EasyTouch system. Special design ash separator provides a clean smoke into the chamber and a natural smoke flavor. In case of sawdust and wood-chips smoke generator, the burning is done by electrical resistance. OptiSmoke is working with an automatic humidification system and also with automatic “firefighter“. Our smoking system is designed to work on the same unit, both with the closed system as well as with the open one. The closed system is working with the recirculation of the smoke and evacuation at the end of the process. The open system is working with continuous exhaust of the smoke and is recommended for different and specific type of products. The automatic cleaning for the smoke generators is controlled by EasyTouch. The smoke generator can be placed next to the chamber, on the left side, on the right side or in the back side. Upon special request, our engineers can design customized, different positions for the smoke generator. Open and Closed Smoking Both systems are available as standard giving the possibility of choosing the optimal smoke circulation depending on the final product.

The Emerson Technik smoking chambers can be equipped with various OptiSmoke smoking generators, depending on the customer’s request or specific local regulations all over the word. Made from solid stainless steel material and resistant at high temperature, OptiSmoke can be used both for hot smoke as well as for cold smoke, given the different type of products. Depending on the application and the capacity of the chamber, we provide the right OptiSmoke smoke generator. It can be ordered for sawdust, wood-chips, friction or liquid smoke. All types of smoke generators are automatic controlled by the main EasyTouch system. Special design ash separator provides a clean smoke into the chamber and a natural smoke flavor. In case of sawdust and wood-chips smoke generator, the burning is done by electrical resistance. OptiSmoke is working with an automatic humidification system and also with automatic “firefighter“. Our smoking system is designed to work on the same unit, both with the closed system as well as with the open one. The closed system is working with the recirculation of the smoke and evacuation at the end of the process. The open system is working with continuous exhaust of the smoke and is recommended for different and specific type of products. The automatic cleaning for the smoke generators is controlled by EasyTouch. The smoke generator can be placed next to the chamber, on the left side, on the right side or in the back side. Upon special request, our engineers can design customized, different positions for the smoke generator. Open and Closed Smoking Both systems are available as standard giving the possibility of choosing the optimal smoke circulation depending on the final product.